OpenPull

Disclaimer: This project is still under development. I have not tested this using a current micropipette. This project uses flamable gas. I am not liable for injury resulted from recreating this project. I am still finalizing design, and am planning to release this project under the Open Source Hardware Association’s guidelines once v1.0 is completed.

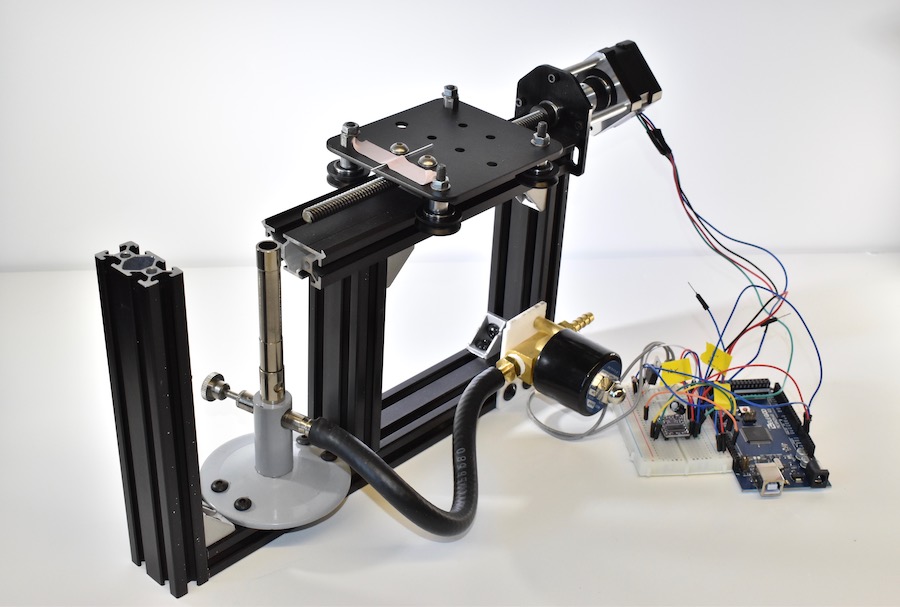

With the advent or Arduino, Raspberry Pi, and commoditization of “jellybean” components, hardware is dropping in price. I want to bring the same access and affordability to bioengineering laboratories. As my first open source project, I designed a micropipette puller.

In order to probe cells and deposit accurate quantities of fluid, biological laboratories use a special machine to accurately make these pipettes. Current machines on the market are thousands of dollars, have a rudimentary user interface (UI).

Technical

An accurate, precise micropipette requires an accurate, precise machine. The main challenge was to find a way to inexpensively provide precise movement. I chose Makerslide because it allowed for zero play adjustment, and easily interfaces with standard-sized aluminum extrusion. To reduce slop as much as possible, I used a four-start lead screw combined with a delrin nut.

In order to provide heating, current micropipette pullers use a high-powered electrical heating element. Using a similar heating element was cost-prohibitive. Instead, I chose to control a bunsent burner using a solenoid valve rated for gas. In order to light the bunsen burner, I ripped out an ignitor/sparker module from a stove/grill lighter. The ignitor runs on a AAA battery, which can easily by replaced by the Arduino’s power pins.

For a frame, aluminum extrusion pieces were faced on a mill, and assembled with 90 degree brackets.

I used an Arduino Uno controller board, combined with stepper motor circuity as shown below. Based on my research, I used the DRV8825 chip since it had a strong following in the open-source community. Switching for the solenoid valve and the stepper motor were accomplished using MOSFETs.

The Arduino IDE does not provide many tools for C++ development. Instead, I used the Atom text editor, with PlatformIO integration.

Result

See picture above.

Review

What went well:

- Project stayed on budget, despite issues with parts compatibility.

- Machining of aluminum parts created a very ridgid frame.

- Parts ordered from Aliexpress were of acceptable quality.

Not so hot:

- Tempermental circuit design for controlling solenoid valve.

- Project incomplete.

Things that still need to be done:

- Micropipette testing, characterization.

- Finalize software

- Finalize electrical circuit design.

- Designing or finding an inexpensive way to hold the glass pipettes without breaking them.